By Rick Sapp, Robin Sharpless

Ready, set, reload!

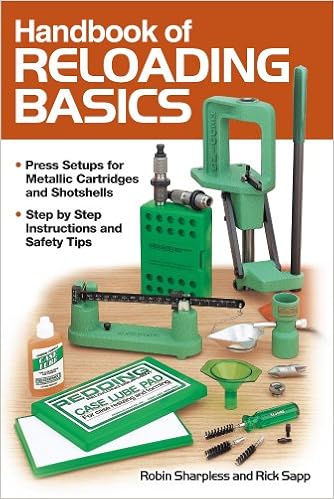

With ammo shortages on retailer's cabinets, exceptional firearms revenues around the state, and burgeoning numbers of latest shooters, reloading is turning out to be in leaps and boundaries. Handbook of Reloading Basics, written by means of specialists Robin Sharpless and Rick Sapp, is aimed squarely on the new handloaders and simplifies either the gear and the method. inside of this bench-handy reference you will discover:

before you purchase your first press, ahead of you polish your brass or type your shotshell hulls you need to learn Handbook of Reloading Basics. This worthwhile reference is the single to get you began and continue you loading round...

Read or Download Handbook of reloading basics PDF

Best miscellaneous books

Formula One Racing for Dummies

At one point, the e-book is an efficient simple precis of F1 racing -- the autos, historical past, tracks, groups and drivers, pointers on attending a race, and a few of the thoughts concerned. if you are a F1 junkie like i'm, its all good.

More objectively notwithstanding, the ebook is dated. .. with information present as much as approximately 2003/04, that's many respects is old historical past for F1 (new diversified replaced teams/drivers/tracks/rules now), so if i used to be simply moving into F1 as a viewer, this booklet will be particularly complicated in view that loads of the information is old-fashioned.

"Your consultant to the realm of Glock. Gaston Glock's progressive pistol is well-known as the most vital and leading edge firearms designs of the final 50 years. considering the fact that its advent in 1983, the Glock has turn into the popular autoloading pistol for numerous legislations enforcement and executive enterprises, army devices, aggressive and leisure shooters, and personal voters.

Prepared, set, reload! With ammo shortages on retailer's cabinets, unparalleled firearms revenues around the nation, and burgeoning numbers of recent shooters, reloading is starting to be in leaps and limits. guide of Reloading fundamentals, written by way of specialists Robin Sharpless and Rick Sapp, is aimed squarely on the new handloaders and simplifies either the gear and the method.

- Sport, Coaching and Intellectual Disability

- Making Sense of Sports

- Contemporary Athletics Compendium, Volume 3

- Gun Digest Book of SIG-Sauer

Extra info for Handbook of reloading basics

Sample text

Remember that, at this point, the case head is no longer seated against the bolt face, as it was driven forward (of course) with the rest of the case by the action of the firing pin’s impact. As the pressure of the second or main pressure curve mounts, though, the rear of the case, wanting to expand to fill the complete cavity of the chamber, now moves back until it impacts the bolt face. This causes the body of the case to stretch, increasing its length, but the stretching isn’t uniform. Because the thinner sections of the case body are firmly gripping the chamber walls, the vast majority of the case stretching occurs adjacent to the web body junction where the transition from the thinner body abruptly changes to the much thicker and non-expanding web section of the case.

A turret support coupled with CNC machining and a heavy backbone on the Redfield T-7 turret press virtually eliminates turret tip under a heavy load. Redding designs its turret presses to actually tip very slightly, but into square rather and out of square. It is an interesting design and one very possible to achieve with today’s CNC machining technologies. The head is of a large diameter to hold the seven die positions, and a very stout spring powers a large-diameter detent ball, which recesses into position on the bottom of the turret head.

While traditional C-frame presses were fine for many smaller cases, they could deflect under the heaviest loads. The advent of the O-frame press was a benefit to reloaders of larger cases, which require heavier sizing pressures. The design of the O-frame press is not really a round “O,” but rather one that more closely resembles a rounded-corner square, with the ram located centrally in the bottom of the “O” and the die attachment point directly above on center. This design improves the elimination of distortion under a heavy load and keeps the die and ram in square, true alignment.